SenseHub® dairy MilkPlus

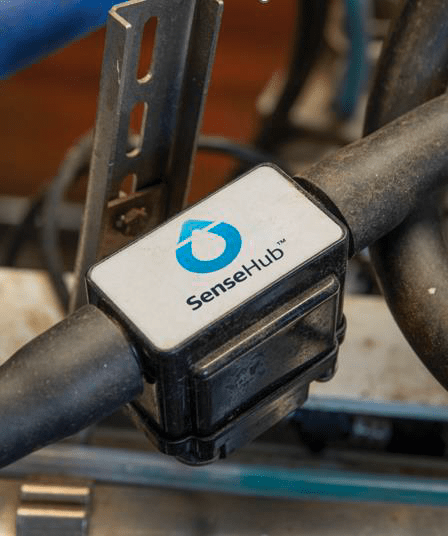

Monitor every cow’s milk yield & components, every day, with SenseHub® MilkPlus sensors.

Get the sense to know her daily milk production, without disrupting your milking routine, with MilkPlus in-line milk sensors installed in your herringbone or rotary cow shed.

SenseHub® dairy MilkPlus

Knowing a cow’s yield, fat & protein is key.

This 6-in-1 sensor measures yield, fat, protein, lactose, blood and conductivity.

Make more informed management decisions using frequent, up-to-date, individual cow milk data throughout her entire lactation, instead of random herd testing.

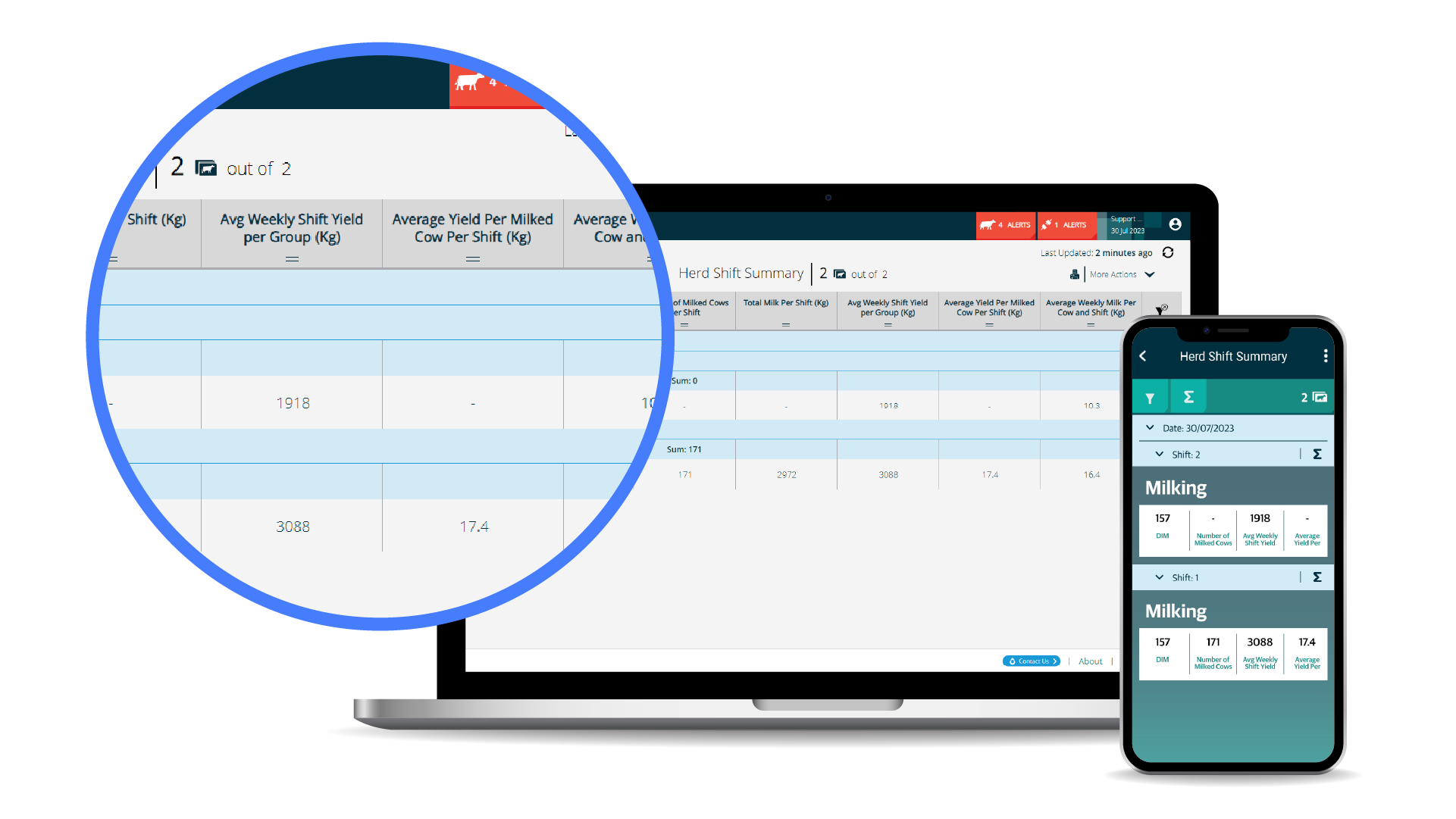

Data is matched to each cow via Entrance ID then stored and displayed in SenseHub® Dairy software, along with data from your cow collars, giving you access to additional reporting and alerts, all in one ecosystem.

The Herd Shift Summary report provides insight into each milking (shift) result by group and compares it to the weekly average. These automated insights enable you to monitor the animals being milked by group, identify any significant changes in milk production by cow, group and/or shift. More insights to support your herd performance.

Milk production insights for each milking (shift) for every animal provides you automated insights that can be used to make decisions that help to maintain optimum health in your cows.

Monitor. Understand. Act.

SenseHub® dairy MilkPlus

Key Features

- Installed in-line

- Measures yield, fat %, protein %, lactose, blood & conductivity

- Stores data in SenseHub Dairy software for viewing and reporting

- Suits herringbone and rotary sheds

- High Blood and Abnormal Milk alerts

- Made in New Zealand

SenseHub® dairy MilkPlus

Benefits

- Doesn’t disrupt your milking routine

- Helps you identify your best and worst producers

- Optimise feed efficiency

- Improve breeding and culling decisions

- Increase production and profitability

- Helps you identify cows that may need vet attention earlier

- Retrofit and install into any current or new sheds

SenseHub® dairy MilkPlus

Compatibility

- Rotary and herringbone sheds

- SenseHub Dairy Premium application plan

- Integrates with SenseHub Dairy collars and drafting

- Schedule auto drafts

SenseHub® dairy MilkPlus

Why Milk Quality Matters

Milk quality is at the heart of every dairy operation, impacting profitability, consumer trust, and herd performance. Delivering high-quality milk requires close monitoring of key milk components, as small variations can signal underlying health, nutrition, or management issues.

Milk Components: a window into herd health & performance

Milk is more than just yield – it contains valuable insights into cow well-being. Monitoring fat, protein, lactose, blood presence, and conductivity provides a detailed picture of milk quality and helps detect early signs of metabolic, nutritional, or udder health challenges.

Fat & Protein: the foundation of milk value

- Fat percentage reflects energy balance – low fat may indicate rumen acidosis, while high fat could signal ketosis.

- Protein percentage is linked to dietary balance and overall cow health. A drop may point to poor digestion, heat stress, or illness

Optimising fat-to-protein ratios helps farmers fine-tune feeding strategies and maintain healthy, high-producing cows.

Lactose: a stability indicator

Lactose plays a key role in milk volume and consumer quality expectations. A decline in lactose percentage can indicate udder inflammation, mastitis risk, or metabolic issues. Tracking lactose trends supports early intervention and milk quality control.

Do I need to be at the computer at the dairy shed to access the system?

No, SenseHub Dairy is cloud-based. That means if you have access to the internet, you can stay connected to the farm from your mobile device from anywhere, at any time.

Blood & Conductivity: early warning signs

- Blood in milk can result from udder injury or infections, impacting milk usability and quality.

- Electrical conductivity is a known indicator of udder health – rising levels may signal inflammation before SCC increases. but often it may also be that there is an immune response before the udder tissue is damaged enough for conductivity to increase.

Monitoring these parameters in real-time helps identify potential health issues sooner, reducing milk losses and supporting better cow care.

sign up or have a chat – leave your details below

Our local Sales Specialist will get in touch soon

want to know more?

Find a Sales Specialist

If you would like more information on SenseHub Dairy monitoring and automation solutions, give your local specialist a call today!

SenseHub® Dairy cow collars offer more accurate heat detection and lower empty rate.

Continue reading >Every cow receives individual attention if she needs it – SenseHub® Dairy cow collars

Continue reading >NZ-SHB-241100006

Argentina

Argentina Australia

Australia Belgium (Dutch)

Belgium (Dutch) Brazil

Brazil Chile

Chile Colombia

Colombia Czech Republic

Czech Republic Finland

Finland France

France Germany

Germany Ireland

Ireland Italy

Italy Japan

Japan Mexico

Mexico New Zealand

New Zealand Norway

Norway Panama

Panama Poland

Poland Portugal

Portugal Spain

Spain Sweden

Sweden United Kingdom

United Kingdom Global

Global